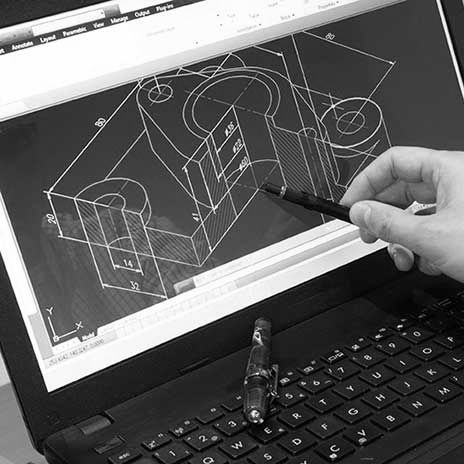

Mould Design

At Petra Associates, we have the experience required to design your new mould tool, so that it performs in the way you want it to; Single or Multi Cavity, Semi or Fully Automatic, Cold or Hot Runner system, Side actions, Up and Away's, Collapsible Cores, Unscrewing Mechanisms.

We select the correct materials to suit the life of the product, from low budget aluminium, to high cost, full hardened H13 tool steel, with everything in between.

We can produce a full Mould Flow Analysis (MFA) of the tool design to highlight possible areas of concern. These can then be rectified before mould tool manufacture begins, saving time and possible post moulding issues. (weld lines, gas traps, sink marks)